Custom Foam Packaging & Foam Dunange

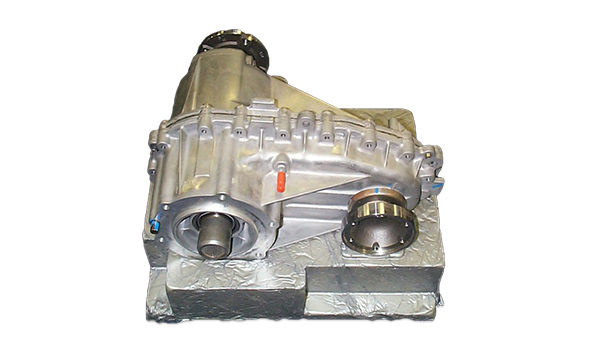

Ameripak designs and manufactures custom foam packaging and foam inserts for a variety of applications. We make custom foam trays, foam end caps, foam materials for medical devices, and other foam dunnage solutions. Foam can be custom-made to any size and thickness.

Common foam materials include: Polyethylene (PE), Crosslinked Polyethylene (XLPE), Polyurethane (PU).

ESD and Anti-Static foam options available.

Check out our CNC machine hard at work!!!